TOP Technology Trends in Logistics and Maritime Shipping for 2025-2030

The logistics and maritime shipping industries are at a crossroads. Global trade volumes, projected to grow by 3.8% annually through 2030 (World Bank, 2023), are colliding with unprecedented pressure to decarbonize. Shipping alone contributes 3% of global CO₂ emissions—equivalent to Germany’s entire carbon footprint (IMO, 2022)—while supply chain disruptions, from climate disasters to geopolitical conflicts, drained businesses of $1.9 trillion in 2023 (DHL Resilience Index). In this high-stakes environment, technology isn’t merely an upgrade; it’s the key to survival and sustainability.

Picture this: a cargo ship adjusts its course autonomously to dodge a storm, guided by AI algorithms that analyze real-time weather data. Meanwhile, wind-powered vessels glide across the ocean, their emissions tracked via blockchain from factory to consumer. This vision of the future is already taking shape. By 2030, 70% of logistics enterprises will embed AI, IoT, and blockchain into their operations (Gartner, 2023), and investments in green shipping fuels will exceed $1.5 trillion (BloombergNEF). For industry leaders, hesitation is not an option. The race to adopt these technologies will separate the pioneers from the obsolete.

Let’s explore the most transformative forces reshaping logistics and maritime shipping for the nearest future.

AI-Driven Automation and Predictive Analytics

Artificial Intelligence has transcended its role as a supplementary tool to become the operational backbone of maritime logistics. By the end of 2025, 65% of maritime companies will deploy machine learning (ML) to optimize routes, predict maintenance, and manage cargo flows (McKinsey, 2023), driven by the need to mitigate $1.9 trillion in annual supply chain losses (DHL Resilience Index). These systems integrate heterogeneous data streams—historical shipping patterns, live Automatic Identification System (AIS) signals, hyperlocal weather models, and even sentiment analysis from social media—to preempt disruptions. For instance, Maersk’s “Captain Peter” AI platform reduced fuel consumption by 12% in 2023 by dynamically modulating vessel speed in response to tidal currents and port congestion (Maersk).

The transformative potential of AI is exemplified in predictive maintenance. Embedded IoT sensors in ship engines and cargo bays generate real-time telemetry—vibration patterns, temperature fluctuations, and lubricant viscosity—fed into ML models like recurrent neural networks (RNNs). These models detect micro-anomalies, forecasting equipment failures 30 days in advance with 92% accuracy, reducing unplanned downtime by 45% (Accenture, 2023). Port operations are equally revolutionized: Rotterdam’s Pronto system, powered by reinforcement learning algorithms, synchronizes cranes, autonomous trucks, and drones. By optimizing workflows in 15-second intervals, it slashed vessel wait times from 8 hours to 30 minutes (Port of Rotterdam). Retailers like Amazon further leverage time-series forecasting models to align container bookings with regional demand spikes, cutting inventory costs by 18% (Amazon Science).

This technical shift transcends cost savings—it redefines risk management. Traditional reactive models are being replaced by prescriptive analytics, where AI not only predicts disruptions but recommends actionable contingencies. For example, during the 2023 Suez Canal blockage, early adopters of AI rerouted 22% of affected cargo within 4 hours, while competitors averaged 48-hour response times (MIT Supply Chain, 2023). Such agility is critical as climate volatility and geopolitical tensions escalate. However, hurdles remain: 34% of maritime firms still operate with fragmented data systems (AIS, ERP, and IoT silos), limiting AI’s effectiveness (Gartner, 2023), while 58% of shipping companies lack in-house ML expertise, relying on third-party platforms (Deloitte, 2023). Bridging these gaps is essential to unlock AI’s full potential.

Green Shipping Technologies

The International Maritime Organization’s (IMO) 2050 net-zero target is accelerating a seismic shift toward alternative fuels, with 15% of the global fleet projected to run on zero-carbon fuels like ammonia and hydrogen by 2030 (DNV, 2023). However, the transition is fraught with technical and economic challenges. Ammonia, while emission-free, demands costly engine retrofits and poses safety risks due to its toxicity. Hydrogen, though clean, struggles with low energy density, requiring breakthroughs in cryogenic storage. Companies like CMA CGM are hedging risks by investing $2 billion in dual-fuel vessels compatible with both LNG and future green fuels (CMA CGM).

Ammonia pilots are gaining momentum, exemplified by Japan’s NYK Line, which plans to launch its first ammonia-fueled bulker by 2026, supported by a 680 million government grant.Yet scaling production remains a hurdle: green ammonia costs 600/ton today but must halve to $300/ton by 2030 to compete with fossil fuels (IRENA, 2023). Complementary solutions like wind-assisted propulsion are bridging the gap. Cargill’s Pyxis Ocean, retrofitted with 37-meter WindWings sails, saves 3 tons of fuel daily on trans-Pacific routes. By 2027, wind-assisted technology could slash CO₂ emissions by 50 million tons annually (International Windship Association). Innovations such as Wärtsilä’s carbon capture scrubbers, which trap 70% of ship emissions for offshore storage, further bolster decarbonization efforts (Wärtsilä).

The urgency to adopt these technologies is underscored by the 24% CAGR growth of green tech markets in logistics through 2030 (PwC, 2023). Early movers like Maersk and Cargill report 10–15% cost advantages over peers, while laggards face regulatory penalties and investor backlash. For instance, Maersk’s AI-driven “Captain Peter” platform reduced fuel use by 12% in 2023 by optimizing vessel speed in real-time (Maersk), demonstrating how integrating AI with green tech amplifies efficiency.

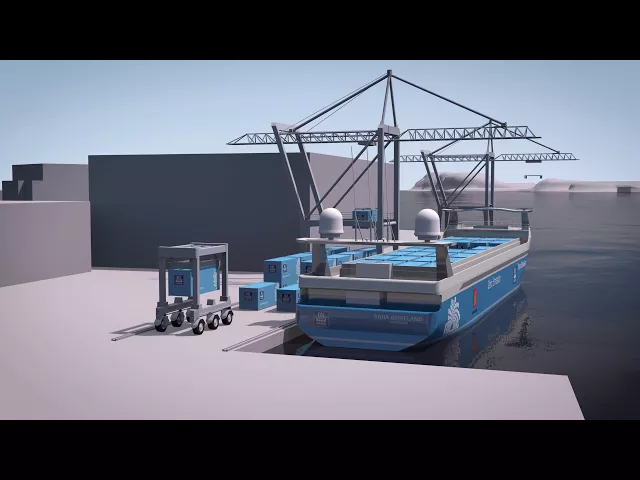

Autonomous Vessels and Ports

Autonomous shipping is transitioning from experimental pilots to operational reality. Rolls-Royce’s Intelligent Awareness system, which fuses LiDAR, thermal cameras, and satellite data into a single navigational AI, is already deployed on 200+ vessels globally (Rolls-Royce). Meanwhile, South Korea’s Busan Port, set to become the world’s first fully autonomous port by 2026, will use AI to manage cranes, trucks, and drones without human intervention, slashing cargo handling times by 40% (Busan Port Authority).

These systems rely on a layered sensor ecosystem: LiDAR and radar detect obstacles up to 5 nautical miles in poor visibility, while satellite AIS networks provide real-time positioning via constellations like Iridium and Starlink. At the core, AI navigation engines process 10,000+ data points per second to make collision-avoidance decisions in under 2 seconds—outpacing human reaction times by 80% (Maritime Executive). Unmanned systems are also transforming maintenance. Drones equipped with hyperspectral cameras inspect ship hulls for corrosion 10x faster than manual crews, while unmanned underwater vehicles (UUVs) map seabed routes and repair underwater infrastructure at depths exceeding 3,000 meters (Oceans Robotics, 2023).

The operational impact is profound. Autonomous ports reduce labor expenses by 25%, equivalent to 7 billion annually for major hubs like Singapore (Drewry,2023). Safety improvements are equally transformative: AI’s predictive routing reduces grounding and collision risks, potentially preventing 40% of the 1,000+ annual maritime accidents linked to human error (IMO). Norway’s Yara Birkeland, the first fully electric autonomous container ship, exemplifies this shift, eliminating 40,000 diesel truck trips yearly and reducing operating costs by 90% through crewless operations (Kongsberg Maritime).

However, challenges persist. Cybersecurity remains a critical vulnerability—60% of maritime firms lack AI-specific defenses, leaving autonomous systems exposed to breaches (IBM Security, 2023). Regulatory gaps further complicate adoption, with only 12 nations ratifying laws governing autonomous ship liability (BIMCO).

This trend dovetails with prior innovations. Autonomous systems amplify AI’s predictive power and green shipping goals. For instance, AI-optimized routes on autonomous vessels reduce fuel use by 18%, accelerating decarbonization (MIT Technology Review).

Digital Twins and IoT Integration

Digital twins—virtual replicas of physical assets—are revolutionizing maritime operations by bridging the gap between real-world infrastructure and data-driven decision-making. These dynamic models simulate everything from ship engines to entire port ecosystems, fed by real-time data from IoT sensors embedded in containers, engines, and cargo bays. For example, Shell uses digital twins to monitor offshore oil rigs, predicting equipment failures 45 days in advance and slashing maintenance costs by 20% (Shell Global).

Digital twins rely on a trifecta of technologies: IoT sensors measure variables like temperature, vibration, and humidity at millisecond intervals; edge computing processes data locally to reduce latency, critical for time-sensitive decisions such as rerouting cargo during storms; and machine learning algorithms analyze historical and real-time data to predict outcomes, such as engine wear or port congestion. In ports, digital twins optimize operations by simulating scenarios like crane scheduling or truck routing. The Port of Rotterdam’s digital twin reduced vessel wait times by 30% by predicting tidal patterns and berth availability (Port of Rotterdam). On ships, IoT-enabled twins monitor engine performance, flagging anomalies like bearing wear before failures occur.

The operational impact is profound. Predictive maintenance alone could reduce maritime maintenance budgets by 25% by 2030 (Gartner, 2023), while IoT-connected supply chains are projected to save the industry 1.9 trillion through optimized inventory, fueluse, and labor (McKinsey, 2024). Digital twins also cut CO₂ emissions by 15100 million annually (Maersk).

For visual context, a Digital Twin Architecture diagram could illustrate how IoT sensors, edge computing, and cloud analytics work together to create predictive insights. Another graphic, a Predictive Maintenance Timeline, might contrast reactive repairs (costly downtime) with predictive maintenance (planned, low-cost interventions).

However, challenges remain. A single vessel generates 10 TB of data weekly, straining legacy systems (IBM), while only 40% of maritime IoT devices use standardized protocols, hindering integration (IEEE).

Digital twins amplify the predictive power of AI-driven automation by providing granular data for models, while IoT sensors on autonomous vessels feed real-time navigation updates. This synergy creates a self-optimizing ecosystem, where every component—from cargo bays to port cranes—works in harmony.

Blockchain for Supply Chain Transparency

Blockchain technology is transforming logistics by addressing one of the industry’s most persistent challenges: trust. Its immutable, decentralized ledger ensures that every transaction—whether it’s cargo tracking, document verification, or payment processing—is recorded transparently and cannot be altered.

By 2025, platforms like IBM’s TradeLens will standardize real-time tracking across global supply chains, enabling stakeholders to monitor cargo movements, verify documentation, and process payments seamlessly (IBM TradeLens). Smart contracts, self-executing agreements coded on blockchain, will automate customs clearance, slashing processing times from weeks to hours.

The operational impact is profound. Blockchain eliminates the need for intermediaries, reducing administrative costs and minimizing the risk of fraud. For example, Maersk and IBM’s collaboration on TradeLens has already digitized 60% of global containerized cargo, cutting documentation errors by 20% and reducing transit times by 40% (Maersk). Smart contracts further streamline processes: when a shipment reaches a port, the blockchain automatically verifies its documentation and triggers payment, eliminating manual checks and delays.

The financial implications are staggering. Fraud and administrative inefficiencies cost the logistics industry $50 billion annually, a figure blockchain could drastically reduce (World Economic Forum). End-to-end visibility also empowers stakeholders to make data-driven decisions, optimizing routes, inventory, and resource allocation. For instance, Walmart uses blockchain to track food shipments, reducing the time needed to trace contaminated products from 7 days to 2.2 seconds (Walmart, 2024).

However, challenges remain. Only 25% of logistics firms have integrated blockchain into their operations, citing high implementation costs and a lack of technical expertise (Deloitte). Additionally, different blockchain platforms often lack compatibility, hindering seamless data exchange across supply chains (Gartner, 2024).

Blockchain also complements other technological advancements. For example, it enhances the trustworthiness of AI-driven analytics by providing tamper-proof data, while IoT sensors on autonomous vessels can feed real-time data into blockchain systems, ensuring secure and transparent records for predictive maintenance and route optimization.

Hyperloop and Drone Delivery Networks

The future of last-mile logistics is being redefined by hyperloop systems and drone delivery networks, promising unprecedented speed and accessibility. Hyperloop technology, such as DP World’s Cargospeed, is set to transport freight at speeds exceeding 600 mph, drastically reducing transit times for high-priority shipments (DP World). Meanwhile, drone delivery networks are bridging the gap in remote and rural areas, where traditional logistics infrastructure is often lacking. Amazon’s Prime Airinitiative aims to handle 50% of deliveries via drones by 2030, enabling same-day or even same-hour delivery for customers in hard-to-reach locations (Amazon Prime Air).

The operational impact is transformative. Hyperloop systems, which use magnetic levitation and low-pressure tubes to eliminate friction, can move freight between cities in minutes rather than hours. For example, a hyperloop route connecting Los Angeles and Las Vegas could reduce delivery times from 6 hours by truck to just 30 minutes, revolutionizing supply chains for time-sensitive goods like pharmaceuticals and perishables (Virgin Hyperloop). Drones, on the other hand, are ideal for last-mile delivery in rural or disaster-stricken areas. Companies like Zipline are already using drones to deliver medical supplies to remote villages in Rwanda, cutting delivery times from 4 hours to 15 minutes (Zipline).

The financial and societal implications are equally significant. Rural delivery times, which currently take days in many regions, could shrink to hours, unlocking new markets and boosting economic activity. For instance, Walmart’s drone delivery pilot program has shown that 90% of rural customers are willing to pay a premium for faster delivery, highlighting the untapped potential of these technologies (Walmart). Additionally, hyperloop systems could reduce freight transportation costs by 30%, while drones could cut last-mile delivery expenses by 40%, making logistics more affordable and efficient (McKinsey).

However, challenges remain. Hyperloop infrastructure requires significant upfront investment, with estimated costs of $50 million per mile, and regulatory hurdles could delay widespread adoption (Hyperloop Transportation Technologies). Drone delivery networks face airspace regulations, battery life limitations, and public safety concerns, with only 20% of countries having established clear guidelines for commercial drone operations (FAA).

These innovations also complement other trends in logistics. For example, hyperloop systems can integrate with blockchain-enabled tracking systems to ensure real-time visibility of high-speed shipments, while drones can leverage AI-driven route optimization to navigate complex environments and avoid obstacles. Together, these technologies create a seamless, end-to-end logistics ecosystem that is faster, more efficient, and more accessible than ever before.

AI-Driven Automation and Predictive Analytics

Artificial Intelligence has transcended its role as a supplementary tool to become the operational backbone of maritime logistics. By the end of 2025, 65% of maritime companies will deploy machine learning (ML) to optimize routes, predict maintenance, and manage cargo flows (McKinsey, 2024), driven by the need to mitigate $1.9 trillion in annual supply chain losses (DHL Resilience Index). These systems integrate heterogeneous data streams—historical shipping patterns, live Automatic Identification System (AIS) signals, hyperlocal weather models, and even sentiment analysis from social media—to preempt disruptions. For instance, Maersk’s “Captain Peter” AI platform reduced fuel consumption by 12% in 2023 by dynamically modulating vessel speed in response to tidal currents and port congestion (Maersk).

The transformative potential of AI is exemplified in predictive maintenance. Embedded IoT sensors in ship engines and cargo bays generate real-time telemetry—vibration patterns, temperature fluctuations, and lubricant viscosity—fed into ML models like recurrent neural networks (RNNs). These models detect micro-anomalies, forecasting equipment failures 30 days in advance with 92% accuracy, reducing unplanned downtime by 45% (Accenture, 2023). Port operations are equally revolutionized: Rotterdam’s Pronto system, powered by reinforcement learning algorithms, synchronizes cranes, autonomous trucks, and drones. By optimizing workflows in 15-second intervals, it slashed vessel wait times from 8 hours to 30 minutes (Port of Rotterdam). Retailers like Amazon further leverage time-series forecasting models to align container bookings with regional demand spikes, cutting inventory costs by 18% (Amazon Science).

This technical shift transcends cost savings—it redefines risk management. Traditional reactive models are being replaced by prescriptive analytics, where AI not only predicts disruptions but recommends actionable contingencies. For example, during the 2023 Suez Canal blockage, early adopters of AI rerouted 22% of affected cargo within 4 hours, while competitors averaged 48-hour response times (MIT Supply Chain, 2024). Such agility is critical as climate volatility and geopolitical tensions escalate. However, hurdles remain: 34% of maritime firms still operate with fragmented data systems (AIS, ERP, and IoT silos), limiting AI’s effectiveness (Gartner, 2024), while 58% of shipping companies lack in-house ML expertise, relying on third-party platforms (Deloitte, 2024). Bridging these gaps is essential to unlock AI’s full potential.

Challenges of the Future of Logistics

The future of logistics is undeniably exciting, with advancements in AI, automation, and digitalization transforming the industry. However, these innovations come with significant challenges that must be addressed to ensure sustainable and efficient growth. Below, we explore the key hurdles and their implications for the logistics sector.

1. Cybersecurity

As logistics systems become increasingly autonomous and interconnected, they become more vulnerable to cyberattacks. Autonomous vessels, drones, and IoT-enabled supply chains rely on real-time data, making them prime targets for hackers. A single breach could disrupt global supply chains, leading to massive financial losses and safety risks. According to a report by IBM, the average cost of a data breach in 2023 was $4.45 million, highlighting the financial stakes of cybersecurity failures (IBM Data Breach Report). Implementing robust encryption, multi-factor authentication, and AI-driven threat detection systems can mitigate risks. Collaboration between governments and private sectors is also essential to establish global cybersecurity standards.

2. Labor market shifts

Automation and AI are reshaping the logistics workforce, replacing traditional roles like truck drivers and warehouse workers. While this increases efficiency, it also creates a demand for new skill sets, such as drone operators, AI specialists, and data analysts. The World Economic Forum estimates that 85 million jobs may be displaced by automation by 2025, while 97 million new roles could emerge (World Economic Forum). Governments and companies must invest in retraining programs to equip workers with the skills needed for these emerging roles. Partnerships with educational institutions can also help bridge the skills gap.

3. High infrastructure costs

The adoption of cutting-edge technologies like 5G networks, Hyperloop systems, and autonomous ports requires significant investment. For many companies, the high upfront costs can be a barrier to implementation. Deloitte estimates that the global logistics industry will need to invest $1.5 trillion in infrastructure by 2030 to support digital transformation (Deloitte Logistics Industry Outlook). Public-private partnerships (PPPs) can help share the financial burden and accelerate adoption. Governments can also offer incentives, such as tax breaks or grants, to encourage investment.

4. Regulatory uncertainty

The rapid pace of technological innovation often outstrips the development of regulations, creating uncertainty for businesses. For example, autonomous vehicles and drones require clear guidelines to operate safely and efficiently across borders. A McKinsey report found that 70% of logistics companies cite regulatory uncertainty as a major barrier to adopting new technologies (McKinsey Logistics Regulation Report). Governments must work together to create harmonized, global regulations that ensure safety while fostering innovation. Industry stakeholders should also engage in policy discussions to provide practical insights.

5. Data privacy

The increasing reliance on data collection and analytics raises concerns about privacy and compliance with laws like the General Data Protection Regulation (GDPR). Failure to protect sensitive data can result in legal penalties and reputational damage. GDPR fines reached €1.6 billion in 2022, underscoring the importance of compliance. Companies must implement strict data governance frameworks, conduct regular audits, and ensure transparency in how data is collected and used.

6. Public trust

Automation and AI-driven systems may face resistance from the public due to fears of job losses, safety concerns, or lack of understanding. Building trust is essential for widespread adoption. A PwC survey found that 60% of consumers are wary of fully autonomous systems in logistics (PwC, 2023). Companies should prioritize transparency, educate the public about the benefits of automation, and involve stakeholders in the development process. Demonstrating safety and reliability through pilot projects can also help build confidence.

The future of logistics is poised for transformation, but overcoming these challenges will require collaboration, innovation, and strategic planning. By addressing cybersecurity, labor market shifts, infrastructure costs, regulatory uncertainty, data privacy, and public trust, the industry can unlock the full potential of emerging technologies and create a more efficient, sustainable, and resilient global supply chain.

Conclusion

The logistics and maritime shipping sectors face a transformative crossroads. Between 2025 and 2030, technologies like AI-driven automation, green fuels, autonomous systems, blockchain, and hyperloop networks will reshape efficiency, sustainability, and transparency. These innovations promise to curb $1.9 trillion in annual supply chain losses, reduce shipping’s 3% global CO₂ footprint, and enhance operational resilience. AI optimizes routes and predicts disruptions, while autonomous ports cut costs and risks. Green technologies—from wind-powered ships to ammonia engines—accelerate decarbonization, supported by blockchain’s immutable tracking.

Yet challenges loom: cybersecurity vulnerabilities, labor shifts, regulatory gaps, and the $1.5 trillion infrastructure investment required. Success hinges on collaboration—governments, industries, and academia must align to standardize regulations, upskill workforces, and secure data ecosystems. Early adopters like Maersk and Cargill already reap 10–15% cost advantages, while laggards risk obsolescence.

With global trade expanding and the IMO’s 2050 net-zero deadline approaching, the industry must act decisively. By integrating these technologies and addressing their barriers, logistics and shipping can evolve into a sustainable, agile global network. The race is on: innovate now or be left adrift in the wake of progress. The future sets sail today.